Dynamic simulation is a specialised simulation method that shows a time based simulation result that can be dynamically viewed and changed during the simulation. Dynamic simulation can be applied to contaminants, gases, DPM and heat.

The key difference between steady state and dynamic simulation is that changing ventilation conditions and contaminants can be tracked through the mine at specific times, and in most cases, the Ventsim model can be dynamically changed (for example different levels of contaminants can be changed, or the model airflows, resistances or fans can be altered) to see the effect on contaminant flow.

View Dynamic Simulation Results

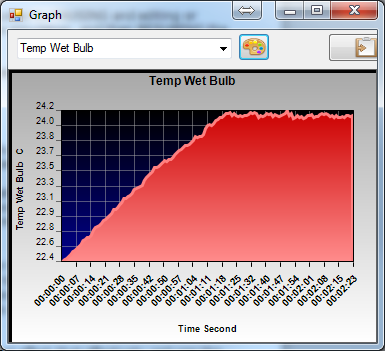

Dynamic simulation employs two methods of observing results. The simulation will dynamically show the on screen results as the simulation progresses. Ensure the text and colours are showing the required simulation data type during the simulation to see the results.

Alternatively, a ‘monitor’ can be placed in an airway to observe and record the simulation changes historically.

![]()

To view the results contained in a monitor, simply click the VIEW button on the monitor to view a graph of results.

Performs a dynamic contaminant simulation based on the position of contaminant source placed in the model.

The simulation will run a continuous time based simulation showing the track and concentration of fumes. The simulation can be paused at any time and the colour or type of data can be changed during the simulation.

Warning: Dynamic contamination in Ventsim uses a simplified homogenous distribution algorithm which ignores the slower turbulent boundary effects of airflow along a rough passage and around corners, and the higher centre airflow velocities. Due to this leading and trailing effect, Ventsim may slightly underestimate the speed of gas distribution, and also underestimate the speed at which all gas is cleared from an airway. The simulation should only be treated as a guide.

Dynamic Contaminant can be applied and set in the EDIT – Contaminant box of any airway, or by using the SMOKE icon on the toolbar. There is no limit to the number of contaminant sources that may be simulated simultaneously in a model.

Dynamic Contaminant Sources may included

- Fixed Time Release

- Linear Decay Release

- Logarithmic Decay Release

- Explosive Gas Release

Fixed / Linear / Logarithmic Release

Selecting these options releases a contaminant for a limited amount of time into the airstream. The amount of time is set in the EDIT box. FIXED release emits the same contaminant level throughout the release time. Linear Decay releases a decreasing amount throughout the release time, starting at the original set contaminant levels, and reducing to zero at a linear rate by the end of the release time. Logarithmic Decay is similar to linear decay, but more rapidly reduces concentration at the start of release time according to a logarithmic power scale.

Time release dynamic contaminants are intended to be used for sudden or limited time release events, such as a stench gas release, gas burst or inundation or tracer gas release, or limited emission of smoke or other contaminants from a source. The simulation is useful for not only detecting the spread concentration, range and timing of contaminants, but also for establishing how long it will take to clear contaminated areas of contaminants.

Dynamic Explosive Contamination

Ventsim 2 utilised a throwback blasting volume method to calculate an initial volume of blast contaminated air that was fed into the mine atmosphere at a decaying rate. This method was restrictive in that the throwback volume factor and the initial throwback volume contaminant concentration must be estimated for each blast.

Actual blasting tends to produce more concentrated initial contaminant volumes for large blasts compared to small blasts. As a result, there was potential to underestimate blast gas concentrations, or underestimated clearance times.

Ventsim 3.0 dynamic explosive contaminant simulation utilises a more automated method and works on the theory that any blasting source will initially produce a mass of pure blasting gases (based on a ‘yield’ factor for the explosives) that must be ‘bled’ into the surrounding atmosphere. Rather than trying to calculate an initial ‘throwback’ volume, the rate at which this pure gas is bled into the surrounding atmosphere is based on an adjustable logarithmic decay series which in the experience of Chasm Consulting appears more consistent with practical measurements of actual blast gas releases underground.

When explosve gas enters a mine airway, the ventilation system must then remove the contaminated air from the region through the rest of the mine to the exhaust. The rate at which the fresh air ventilation can initially remove the contaminant depends on the efficiency of the ventilation flow to access and remove all fumes from the blast zone (labeled the ‘dispersion factor’ in Ventsim).

For example, in an open free flowing drive with good airflow, contaminant would be expected to be removed quickly as the fresh air forces all pockets of fumes and gas quickly down the drive. A blind heading, ventilated by duct which may be damaged or some way away from the heading end will clear slowly as the fresh air cannot efficiently reach all parts of the drive and remove the fume.

The intial blast gas concentration mixing into the atmosphere is automatically calculated by Ventsim and is based on the blast size and the dispersion factor. This value is shown as an estimate in the EDIT box.

Results for Version3.0 in most cases should be similar to Ventsim 2.0, however for large blasts, initial gas concentrations may be higher than determined by the user, and clearance times may be shorter.

Dispersion Rate

Ventsim uses logarithmic decay series to determine the portion of injection of blast gases into the atmosphere. The decay series uses a ‘dispersion’ factor of between 0 and 10 to control the logarithmic decay rate.

The dispersion factor is a unitless number that uses a square power series to describe the rate of gas removal. For example, a factor of ‘2’ will initially release the explosive gases into the atmosphere at twice the rate of a factor of ‘1’. A factor of ‘4’ will initially release the explosive gases at twice the rate of ‘2’, creating an intially more toxic atmosphere, but clearing more rapidly. These factors are somewhat subjective (Ventsim describes ‘1’ as

very slow dispersion and very fast as ‘10’) and it is suggested that mine use a gas detection meter to gain an understanding of their dispersion rates for different blast and ventilation scenarios. Once Ventsim simulation are calibrated with the blast results, the factors can be more accurately determined and used with more confidence in other areas.

The contaminant and explosive concentration and amount can be placed with the SMOKE button and can be changed in the EDIT – Contamination box. A unlimited number of dynamic sources can be placed throughout the model, each with a different blast size and clearance rate (to simulate a number of development headings and stopes firing simultaneously for example).

Explosive Gas Release Settings

The yield rates of explosive gas release can be established in the Contamination Simulation settings. The default yield rates are based the number of kilograms of Carbon Monoxide release per kilogram of explosive blasted as measured by Orica. This yield factor can be changed or made to represent other types of gases. The concentration units entered can be changed to any concentration based unit (eg %, ppm, mg/m3 etc) in the settings. The unit name can also be changed in the Settings > Contamination menu section. The simulation is activated from the Run menu or from the Contaminant Simulation side button access.

EXAMPLE : Blasted development headings have been previously measured to initially have up to 2000 ppm of CO carbon monoxide immediately after blasting and a clearance time of 15 minutes. Therefore a dispersion factor is entered into the EDIT box to obtain a similar result (the setting unit can be changed to “CO ppm” if the user selects), and the explosive amount set to 200 kg. When dynamic simulation is chosen, the concentration of fumes (in ppm CO) is shown through the model second by second. Clearance times can be established when concentration falls below a specified limit (for example 25 ppm). At any time, the colour legend and limits can be changed to show the concentration as colours.

Warning : Dynamic contaminant simulation has many factors which can initially be difficult to predict. It is highly recommended users calibrate their models with actual data if they have the opportunity. The simulation does not replace real gas measurement or observation when entering blasting areas.

Dynamic gas simulation simulates the time based spread of gases through a mine. Once again, the dynamic monitor functions can be used to record historical gas results from the simulation at different locations.

For further information see the GAS SIMULATION chapter.

Dynamic Heat Simulation is a potentially complex function that can help determine transient or changing mine temperature based on changing conditions through the mine.

For example, surface temperatures, machines, refrigeration or mining activities can be changed during the dynamic simulation to determine the effect of the changes over time on the mine atmosphere at different locations in the mine.

To calculate the true dynamic effects on the mine atmosphere, the mine rock surface boundaries must be considered to have reached a stable boundary temperature so that short term changes in mine atmosphere temperatures can be released or absorbed by the rock at levels similar to the initial rock exposure receptiveness.

This creates a ‘thermal’ buffer or flywheel effect that effectively reduces the downstream impact of rapid temperature changes on the mine atmosphere. The thermal flywheel effect diminishes with exposure time; however for the short term dynamic simulation term that this function is designed for, the assumption of the rock boundary layer achieving a stable temperature produces reasonable results. To adjust for longer term exposure during dynamic heat simulation, Ventsim creates a boundary layer of rock of a predetermined thickness that is allowed to store or release heat during simulation.

The settings in the DYNAMIC > VENTFIRE™ section provide some level of control over the way this function works on the mine atmosphere.

For more detail on this function, see the VentFIRE ™ section of the manual. For complex dynamic heat simulation, the VentFIRE™ module is recommended as it allows pre-programmed heat and temperature changes to be included in the modelling, rather than manually pausing and changing the simulation.

For further information on steady state heat or dynamic heat simulation, see the THERMODYNAMIC SIMULATION chapter or the VENTFIRE™ section.

Warning : Due to the nature of short term dynamic heat simulation, it may not predict exactly the same results as steady state heat simulation. If this is required, the SETTING > DYNAMIC > VENTFIRE™ option for Dynamic Rock Age may need to be increased, however this will impact on the Thermal Flywheel effect during simulation.